With high degree of respect on your demand Schmidt + Bender Hungaria Optics Ltd. is now offering excellent performed optical coatings. Our engineering team including the optical thin film development department is continuously working on satisfying all of our customers’ needs. Our state-of-the-art equipped laboratory and manufacturing environment also let us provide any solutions which meet all of your specifications. In case of special inquiry we are even cooperating with many academic professors at the worthily famous Budapest University of Technology and Economics as well.

PRODUCTION

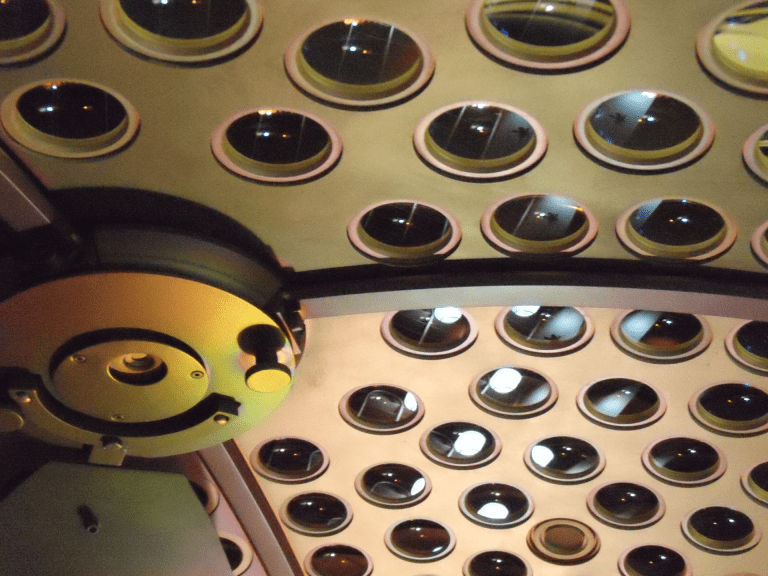

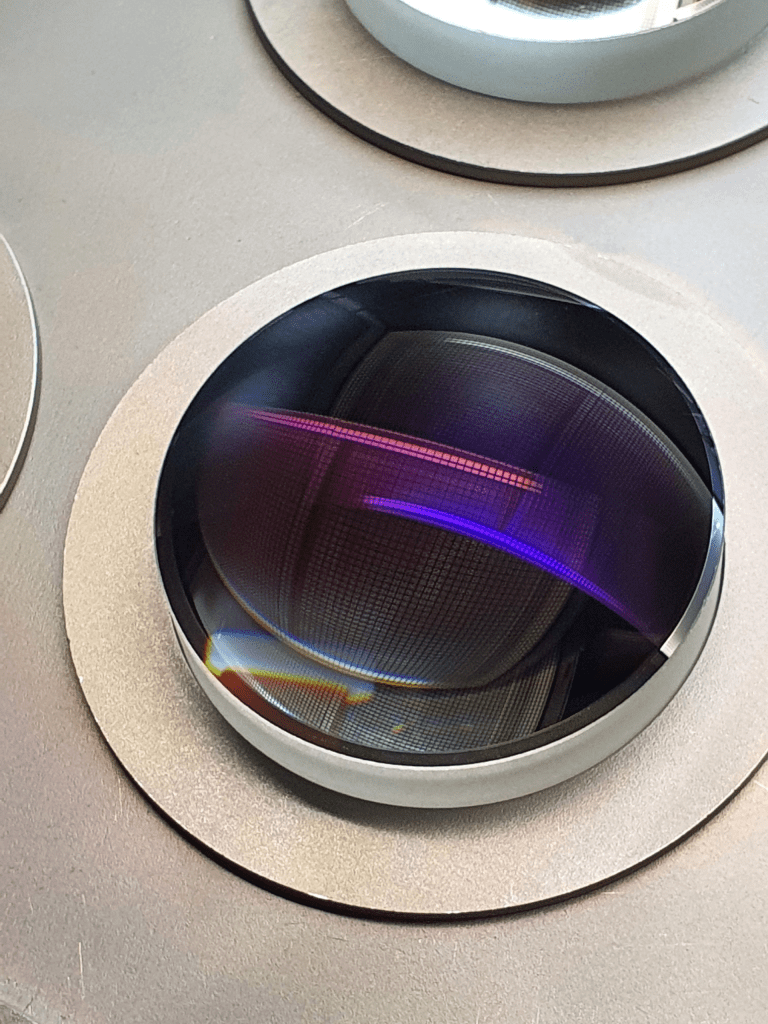

Our product line includes a variety of dielectric and metallic coatings for the wavelength range of 190 nm to 3000 nm.

TECHNOLOGY

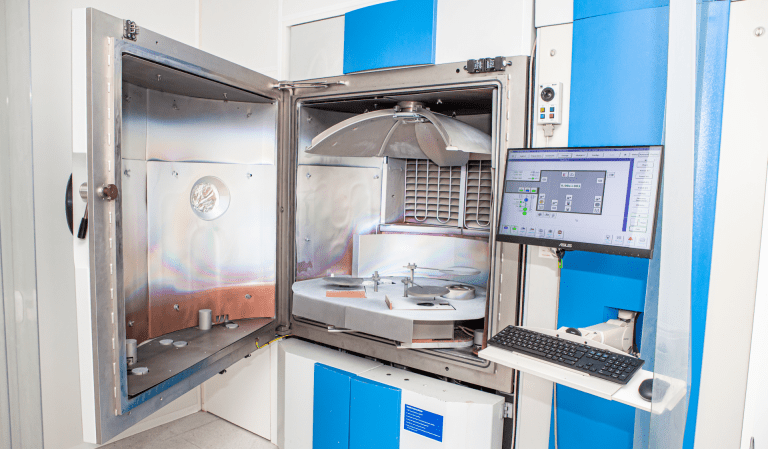

The coatings are deposited by both conventional and plasma enhanced technology depending on the requirements. All types of optical materials and crystals are suitable for coatings. (e.g. Schott, Ohara, CDGM, etc.) The substrates are usually supplied by the customer but we are also offering solutions “from blueprints to complete systems” thanks to the pioneer, historical Hungarian optical manufacturers.

Please take a look on the following short list of some coating types available may satisfy you.

ANTIREFLECTION COATINGS

- Single layer antireflection coatings

- Antireflection coatings for individual and multiple laser wavelengths

- Broadband and Super-Broadband antireflection coatings

- “Multi-Wave” antireflection coatings

- Custom antireflection coatings to customer specifications

MIRRORS

- Dielectric high reflectors

- Bare and protected metallic mirrors of Al, Ag or Cu

- Enhanced metallic mirrors

- Front and Back side mirrors are available depending on the functions

FILTERS

- Edge filters (short or long wave pass filters)

- Band pass filters

- Dichroic filters

- Custom filters according to customer requirements

BEAM SPLITTERS

- Polarizing beam splitters (cemented or separate elements)

- Non-polarizing beam splitters (cemented or separate elements)

- Immersed beam splitters

- Partial beam splitters (partially transmitting mirrors)

- Custom made beam splitters

DEVELOPEMENT

Right after receiving your inquiry our development team is immediately working on the project in order to come up with the most cost effective, reproducible and stable process. Until the coating design has been approved we are closely cooperating with our customers directly by reporting the theoretical or current performance to proof that the specifications will be achieved.

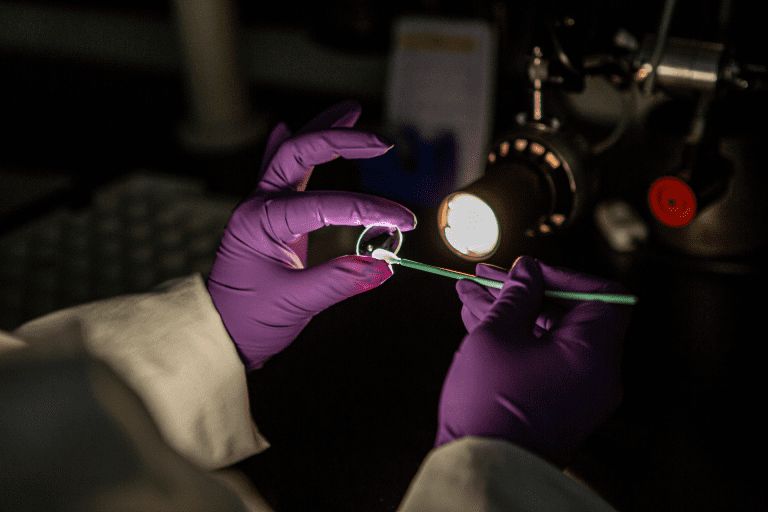

QUALITY

Of course all of our price quotation will fully include the necessary development-, tooling-, and preparation costs such as the substrate fine-cleaning as well as any further kind of process such as cementing. If the customer desires we also provide optical flats (witness pieces) coated directly with the products in every single batch. These samples are marked by the batch number and it is intended to serve the inspection of the final spectral performance.

EGYENLETES RÉTEGVASTAGSÁG

MODERN VÁKUUM KAMRA

NAGY TISZTASÁGÚ OXIDOK

PRECÍZIÓS TISZTÍTÁS

VEVŐSPECIFIKUS MÉRETEK

TÜKÖRBEVONATOK FÉMGŐZÖLÉSE